Product Description

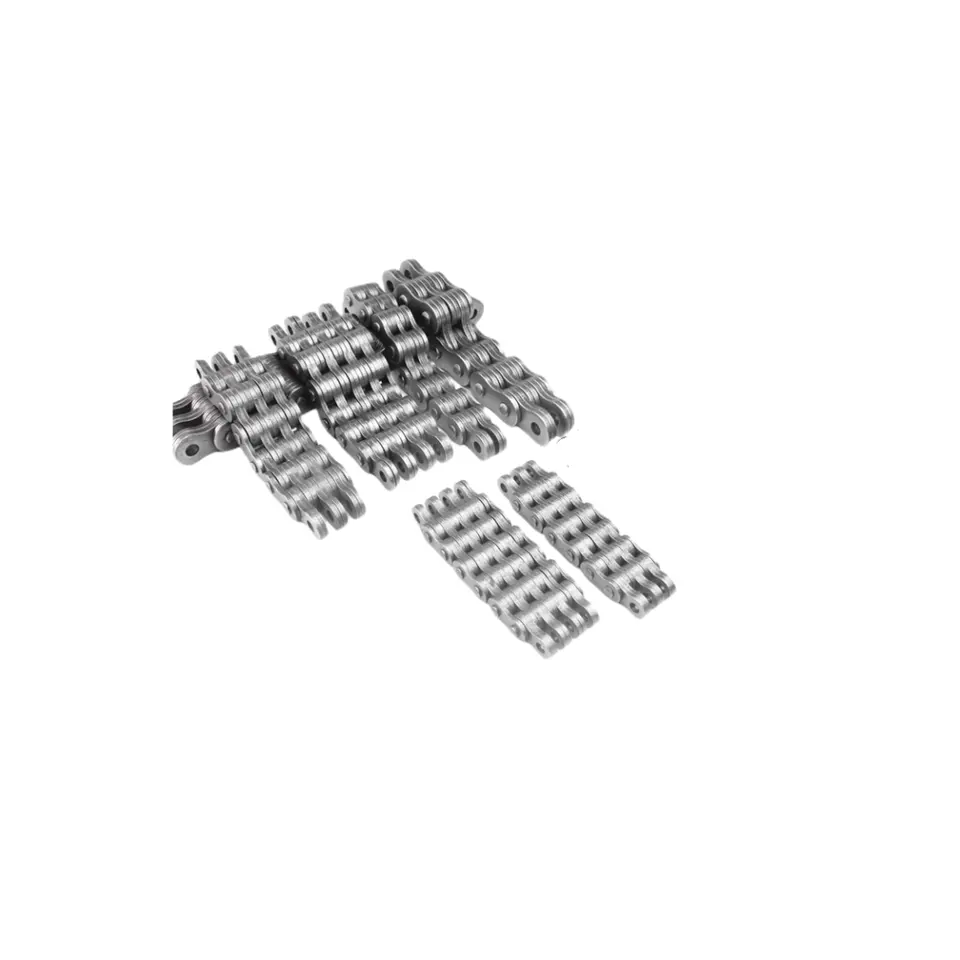

Made-to-order Alloy/Carbon Steel Dacormet-Plated Leaf Chain

Product Description

1. The Product Series: BL, AL, LL, FL, etc

2. Material: Alloy steel & Stainless steel 304

3. Surface Treatment: Shot peening / Blackening / Dacromet-plated / Nickel-plated / Zinc-plated, etc

4. Application: This type of chain can be used in CHINAMFG forklift truck, UniCarriers forklift truck and other brand of forklift truck.

5. Chain No:

AL322, AL344, AL422, AL444, AL466, AL522, AL534, etc.

Plate lacing: 2*2, 2*3, 3*4, 4*4, 4*6, 6*6, 8*8.

| Product name | Leaf Chain Series Used in Sewage Treatment From China Factory |

| Materials Available | 1. Stainless Steel: SS304 , SS316, etc |

| 2. Alloy Steel: 45Mn, 42CrMo, 20CrMo, etc | |

| 3. OEM according to your request | |

| Surface Treatment | Shot peening, Blackening, Oxygenation, Polishing, Zinc-plated, Nickel-plated, Anodized, etc. |

| Characteristic | Fire Resistant , Oil Resistant, Heat Resistant |

| Design criterion | ISO DIN ANSI & Customer’s Drawing |

| Size | Customer’s Drawing & ISO standard |

| Application | Forklift, Hoister, etc |

| Package | Wooden Case / Container and pallet, or made-to-order |

| Certificate | ISO9001: 2008 |

| Advantage | First quality, Best service, Competitive price, Fast delivery |

| Delivery Time | 20 days for samples. 45 days for official order. |

Detailed Photos

View more products,please click here…

Company Profile

| Material: | Alloy/Carbon Steel |

|---|---|

| Structure: | Leaf Chain |

| Surface Treatment: | Dacormet-Plated |

| Chain Size: | Al322, Al344, Al422 |

| Feature: | Heat Resistant, Corrosion Resistance |

| Sample: | for Free |

| Samples: |

US$ 0/Meter

1 Meter(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the safety considerations when working with leaf chains?

Working with leaf chains involves several important safety considerations to ensure the well-being of personnel and the proper functioning of the lifting equipment. Here are some key safety considerations:

- Proper Installation: Leaf chains should be installed correctly according to the manufacturer’s guidelines and specifications. Improper installation can lead to chain failure and accidents.

- Regular Inspection: Regularly inspecting the leaf chains for signs of wear, damage, or misalignment is essential. Any issues should be addressed promptly to prevent potential hazards.

- Load Limits: Adhere to the load limits specified by the chain manufacturer. Overloading the leaf chain can result in excessive stress and may cause it to fail.

- Environmental Considerations: Consider the operating environment of the leaf chain, such as temperature, moisture, and chemical exposure. Some environments may require special chain coatings or materials for optimal performance and safety.

- Training and Certification: Operators and maintenance personnel should receive proper training in the safe use, inspection, and maintenance of leaf chains. Certification may be required for specific lifting operations.

- Chain Lubrication: Proper chain lubrication is essential to reduce friction, wear, and the risk of chain failure. Follow the manufacturer’s recommendations for lubrication frequency and type.

- Replacement of Worn Components: If any part of the leaf chain shows signs of wear or damage beyond acceptable limits, it should be replaced promptly with the appropriate spare part.

- Clear Communication: Maintain clear communication among all personnel involved in the lifting operation to ensure coordinated and safe movements.

- Emergency Procedures: Have clear emergency procedures in place in case of chain failure or accidents. This includes emergency stop controls and evacuation plans.

By following these safety considerations and adhering to industry standards and regulations, users can enhance the safety and reliability of working with leaf chains in lifting applications.

Remember that safety is paramount when working with any lifting equipment, and taking a proactive approach to safety can prevent accidents and injuries in the workplace.

What are the benefits of using a leaf chain in wastewater treatment and sewage systems?

Leaf chains offer several advantages when used in wastewater treatment and sewage systems. These systems require reliable and efficient equipment for handling heavy loads, moving large components, and maintaining smooth operation. Here are the benefits of using a leaf chain in such applications:

- High Load Capacity: Leaf chains are designed to handle heavy loads, making them suitable for the rigorous demands of wastewater treatment and sewage systems.

- Robust and Durable: Leaf chains are constructed with high-quality materials and undergo precise manufacturing processes, ensuring their durability and resistance to wear, even in harsh and corrosive environments commonly found in sewage systems.

- Low Stretch: Leaf chains have low elongation, providing accurate and consistent movement, which is essential in wastewater treatment processes.

- Reliable Performance: Leaf chains offer stable and reliable performance, reducing the risk of downtime and ensuring the continuous operation of wastewater treatment and sewage systems.

- Minimal Maintenance: When properly selected and maintained, leaf chains can have a long service life with minimal maintenance requirements, contributing to cost-effective operations.

- Wide Range of Sizes: Leaf chains are available in various sizes and configurations, making them adaptable to different equipment and applications in wastewater treatment and sewage systems.

In wastewater treatment and sewage systems, leaf chains are commonly used in various equipment, such as sludge scrapers, clarifiers, grit classifiers, and other components that require lifting, conveying, or pulling operations. Their robust construction and reliable performance make them an ideal choice for these critical applications.

As with any equipment used in wastewater treatment and sewage systems, regular inspection, maintenance, and adherence to safety guidelines are essential to ensure the proper functioning of leaf chains and the overall system.

editor by CX 2023-11-07